EdgeMaster™ 2

The EdgeMaster™ 2 is a photoelastic stress analysis system optimized for measuring edge stresses in clear or tinted glass, and glass with or without black paint. The system works on windshields, sidelights, and backlights.

Product Overview » Grey-Field Polariscopes » GFP2600 Product Line

Product Overview » Grey-Field Polariscopes » GFP2600 Product Line

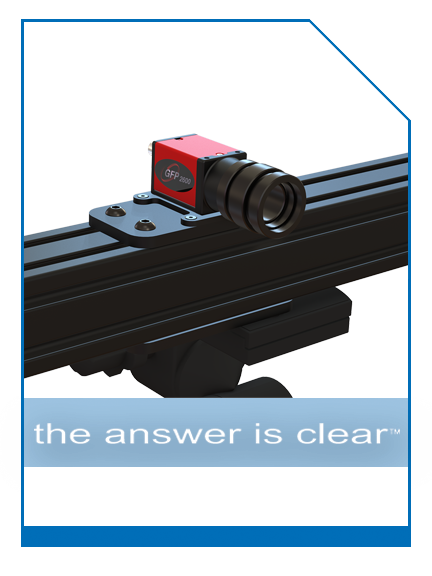

The GFP™2600 Real-time Photoelastic Stress Analysis (PSA) Systems instantaneously acquire stress images, or videos, via kaleidoscopic optics. The systems create multiple copies of stress images—all exposed to different sets of polarizing optics to measure stress in transparent materials, such as glass, silicon wafers, silicon coated glass and many ceramics. The system can measure stress through painted glass by reflecting light off the paint and can measure load-induced surface strains on opaque materials with applied strain sensitive coatings.

Each PSA system consists of a GFP™ (Grey-Field Polariscope) camera head, an illuminator, and a framework that ties the system together. Selection of lenses can further customize the systems to measure stress in a broad range of materials.

The GFP2600 Photoelastic Stress Analysis (PSA) System is managed with easy to use DeltaVision™ software—a versatile tool for capturing, presenting, analyzing, and archiving photoelastic data.

The GFP™2600 Real-time PSA System is one of the fastest stress measurement instruments Stress Photonics offers. The camera is easily incorporated into targeted inspection systems, from handheld tools to online installations. The most popular GFP2600 systems are shown below.

This video demonstrates real-time strain analysis of a 3 Mil LDPE (Low Density Polyethylene) plastic sheet acquired with the GFP2600 PSA (Photoelastic Stress Analysis) System.

This video demonstrates real-time strain analysis of a 3 Mil LDPE (Low Density Polyethylene) plastic sheet acquired with the GFP2600 PSA (Photoelastic Stress Analysis) System.

Below is a sampling of GFP™2600 images.

| SPECIFICATION | VALUE |

|---|---|

| Size | 76mm w × 105mm h × 60mm d |

| Range | 1000nm |

| Repeatability | 2% |

| Accuracy | 0–10nm ± 0.5nm 10–100nm ± 5nm 100nm ± 5% |

| Frame Rate | 10 f/s |

| Resolution | Pixel Resolution: 2750 × 1080 |

| Lenses | Any C-Mount Lens |

| Interface | GigE |

| Specifications are general. Definitive specifications are determined by application and will be reflected in final quote. |

Need help? Email our expert support team via our contact form or call us at +1 (608) 224-1230

Need help? Email our support

team via our contact form

or call us at +1 (608) 224-1230

Glass Photonics was founded by Stress Photonics Inc to better serve the glass industry.

All products are manufactured by Stress Photonics.